POLYCAB BMS CABLE

Polycab’s BMS (Building Management System) Cable is a specialized solution for efficient and reliable data communication within building automation networks. Engineered for seamless integration with modern control systems, this cable ensures secure and accurate transmission of signals and data. Trust Polycab for a high-quality BMS cable designed to meet the demands of smart building technologies, ensuring optimal performance and connectivity.

Description

BMS cable also known as Building managament system cable, is used in Intelligent controller for moinitoring and control of building utility system such as air conditioning, ventilation, lighting, hydraulics, etc. Functionally it links with individual unit of building equipement so that operation can be done in one complete integrated system. Such integrated systems require BMS cable to interconnect. The cables are supplied with EMI suppression facility with the help of metallic screen to provide noise free signal in BMS systems.

Polycab’s BMS cables are preferred choice for Building management system applications.

The design of BMS cable is based on national & internantional standards as available to meet the service requirement. The screening type of BMS cables designed and manufactured by POLYCAB, reduces the external noise pick up in the circuit, there by reduces the interference.

POLYCAB is a leading manufacturer of a comprehensive range of BMS cables and we can offer the right product for right application.

Caution: BMS cables are not designed for use with power supplies and should not be connected to the mains power.

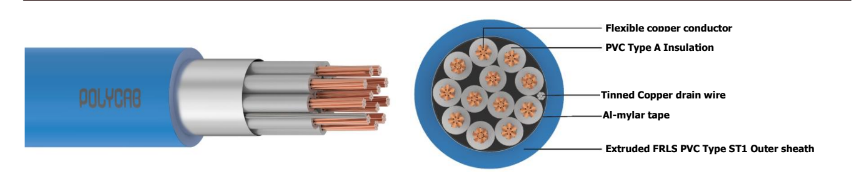

Conductor: High conductivity annealed plain flexible copper conductor produced in-house from state-of-the art machine.

Insulation: In-house developed PVC insulation compound having high insulation properties.

Collective screen: Shielding type Aluminium-Mylar tape with tinned copper drain wire.Drain wire will continuous contact with aluminum side of the tape. Shielding with ATC braiding can also be provided to meet the specific requirements.

Outer Sheath: In-house developed thermoplastic compound having low emission of smoke and corrosive gases when exposed to fire.