Polycab Extra High Voltage cables

Polycab offers Extra high Voltage Cable with Copper as well as Aluminum conductor in the range of 66 KV to 220 KV for underground installation for 3 Phase AC circuit. Polycab’s rich experience and advance technology made the cable superior to use for a service life of 40 years. These cables are mainly used to supply power from the power station to distribution unit or substation. Polycab has set up it’s largest High Voltage cable manufacturing plant in Halol, Gujarat districts near Mumbai invested in state-of the art machines like Maillifer, Scolz, John Royale along with a modern testing facility. The plant is equipped with high automation for material feeding to avoid contamination and electrical failure as well as high speed stranding machines for classic conductor preparation.

Outstanding Features

• High life

• UV resistance

• Longitudinal water resistant

• Radial water resistant

Description

CONDUCTOR

In house developed high conductive Copper or Aluminum is used for EHV Cable for highest degree of transmission. Polycab supplies two types of coductors: Stranded compacted round and stranded segmental Milliken conductor beyond 800 Sq.mm.

The large conductor divides into no. of segments followed by converging spirally to form a circular conductor. The Combination of segmental structure suppress the skin effect and proximity effect resulting low conductor resistance and improving the current rating capacity. Upon request Polycab can supply water tight conductor with improved design.

CONDUCTOR SCREEN

The conductor screen consists of an extruded layer of semiconducting thermosetting compound which completely covers the whole surface of the conductor and firmly bonded to the XLPE insulation layer. A non hygroscopic semiconducting tape may be applied on the conductor if required.

INSULATION

In-house developed high insulation resistance cross-linked polyethylene thermoset insulation compound.

NON-METALLIC INSULATION SCREEN

An extruded layer of cross-linkable semi conducting compound, applied in triple extrusion with conductor screen and insulation extrusion, to eliminate micro voids and curing resulting longer life of cables.

Shield: Copper wires / Aluminium wires / Aluminium corrugated sheath / lead (or) lead alloy sheath to carry fault current, semiconducting tape may be applied for wire shielding.

Outer Sheath: In-house developed thermoplastic High Density polyethylene compound having low emission of smoke and corrosive gases when exposed to fire, semiconducting layer may be applied.

Voltage Rating

Nominal Voltage: 38/66 kV (72.5 kV)

Operation Temperature

Max. operating temperature: +90°C

Max. Short Circuit Temperature: 250°C

Construction

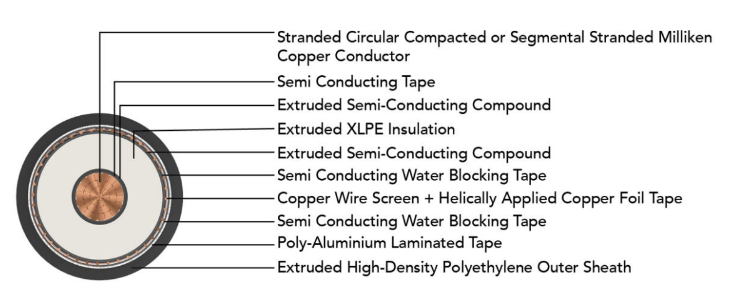

• Conductor: Circular Compacted or segmental stranded Milliken Copper conductor as per IEC 60228, class 2

• Separator: Semi Conducting Tape

• Conductor Screen: Extruded Semi-conductive compound

• Insulation: Crosslinked polyethylene

• Non-Metallic Insulation Screen: Extruded Semi-conductive compound

• Separator: Semi Conducting Water Blocking Tape

• Metallic Insulation Screen: Copper Wires + Helically applied Copper Foil Tape

• Separator: Semi Conducting Water Blocking Tape

• Shield: Poly-Al. laminated Tape

• Outer Sheath: Extruded High-density polyethylene (HDPE), Colour: Black

• Optional Semi-conductive layer