Polycab Marine cables in compliance with IEC specification & standard

Polycab’s Marine Cables, crafted in accordance with IEC specifications and standards, are designed to meet the rigorous demands of maritime applications. Engineered for reliability and durability, these cables ensure secure power transmission and communication in marine environments. Trust Polycab for high-quality marine cables that adhere to international standards, providing a robust solution for a wide range of maritime applications.

Outstanding Features

•Halogen Free

• Reduced Flame Propagation

• Flame Retardant

• Low Smoke Emission

Description

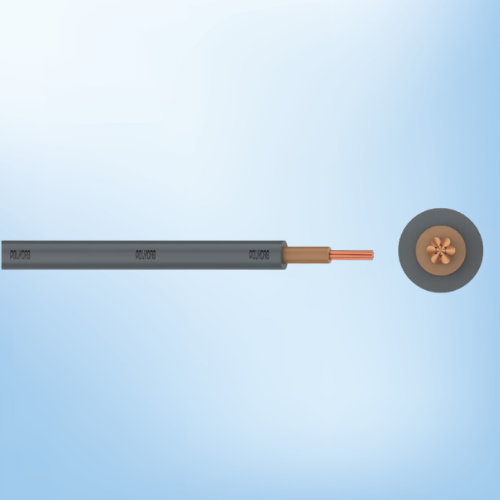

These are low voltage (0.6/1.0 kV & 1.8/3.0 kV), medium voltage (6.0 kV to 20 kV) & instrumentation cables (150/250V) in fire retardant and fire resistant combinations confirming to the construction and performance as per IEC 60092-353, 354, 376, 350, 352, 360. These cables are suitable to use in fixed installation in power, lighting, control, instrumentation and communication circuits on sea/marine vessels and offshore platforms where peak / transient voltages occurs during motor operations / variable frequency drive applications.

These are single / multi core/pair cables with maximum conductor operating temperature of 90 ̊C and maximum conductor short circuit temperature 250 ̊C, produce low level of smoke and corrosive gases when exposed to fire than compared cables manufactured in accordance with IEC 60092-353, 354, 376.

Conductor: High conductivity annealed plain stranded copper conductor produced in-house from state-of-the art Contirod line.

Insulation: In-house developed high insulation resistance cross-linked polyethylene thermoset insulation or Ethylene propylene rubber.

Individual Shield: Where required Pairs are shielded with Aluminium. Mylar Tape along with drain wire Laying up of Multi Cores / Pairs.

Inner Covering/ Inner Sheath/ Protective Tape: A protective barrier created between insulation and armour/braid/screen by extruded layer of polymeric material or Protective tape.

Collective Shield: Where required laidup Pairs are shielded with Aluminium. Mylar Tape along with drain wire Metallic Braid / Screen: Copper Braiding / Screening is provided to allow the cable to withstand mechanical stresses to which it is exposed.

Sheath: In-house developed thermosetting polyolefin compound type SHF-1 / SHF-2 having free from halogen, low emission of smoke and corrosive gases when exposed to fire.

The construction based on the application and requirement of the user against above mentioned IEC standards.

Related Products

Polycab, PVC insulated and PVC sheathed control cable conforming to BS 6004 standard

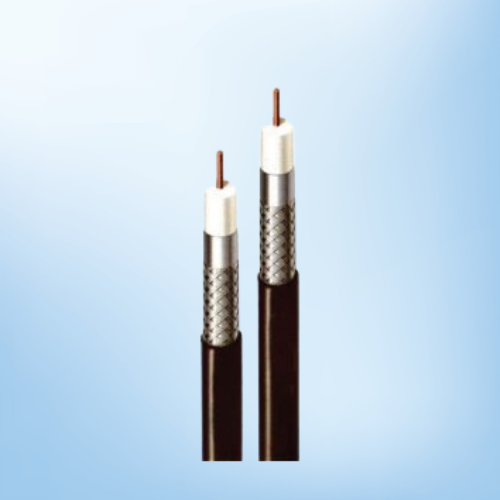

JELLY FLOODED COAXIAL CABLES

- Minimum loss in signal quality: better reception

- Higher band width: larger network expansion, 100 plus channels

- Low attenuation value : less electromagnetic interference

- Minimum structural return loss. Moisture proof: Ideal for tropical conditions